Telescopic Chute Manufacturer In Kolkata

Telescopic Chute Manufacturer

Telescopic Chute Manufacturer In Kolkata

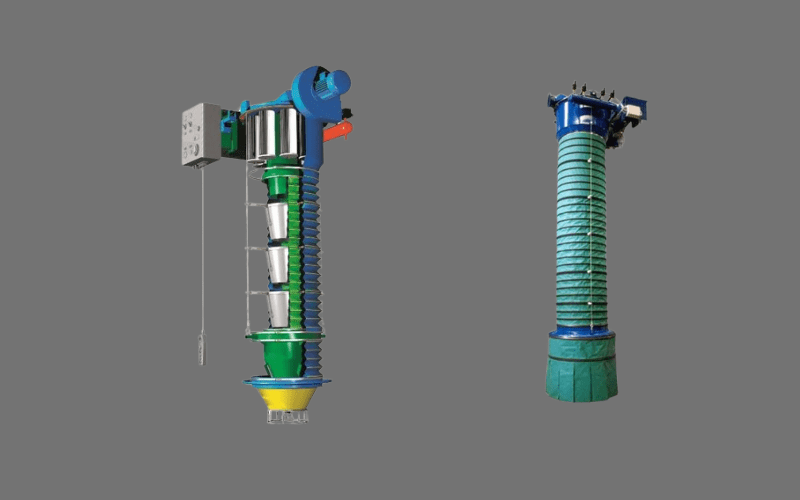

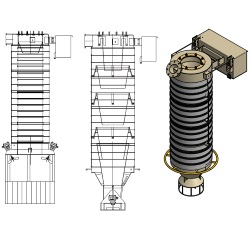

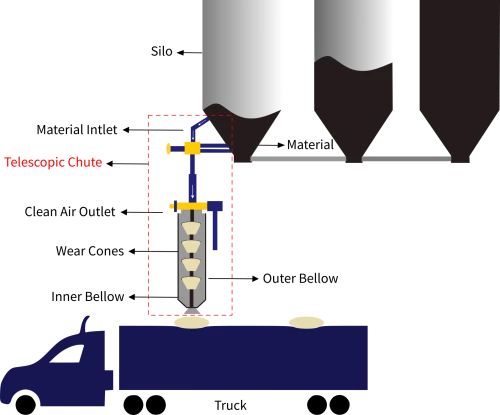

It comprises of inner sections which can be either conical or cylindrical, which contains the bulk material flow. An outer bellow which is flexible is used to limit the propagation of dust.

In case of mechanized warehouses, telescopic loading spout is used for maintaining dust free environment by containing the dust discharged from height. The equipment helps in maintaining clean and healthy environment form employees.

S. N. Welding Works manufactures both the type of standard models of Telescopic Chute as well as customized one as per the need of the client and the application. It comes with cones or cylinders with different materials of construction like mild steel, Sailhard, Hardox, stainless steel etc. depending on the need. S. N. Welding Works designs, manufactures and supplies Loading Spout with either motorized (winching) arrangement or even pneumatic arrangement wherever space is a constraint.

Types of Loading Chutes

- Closed Telescopic Loading Chutes

- Open Loading Chutes

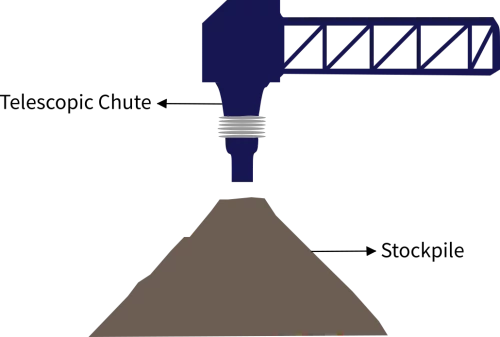

Open Loading

Telescopic open loading chutes are used to fill flatbed open trucks, ships and stockpiles where bulk material is directly exposed to the environment. At the beginning of loading, the telescopic chute is lowered towards the flatbed of the truck / ship or basement and stops at the bottom. Material falls freely through the telescopic chute. Flexible dust skirt located at the bottom side of the chute keeps the dust content inside the loading region. Additional vacuum air supplied by the dust collection system ensures that any dust emission is prevented effectively. Level sensors installed on the unit are used to check product level continuously. As the product level increases, the telescopic chute raises automatically. After loading is completed, the telescopic loading chute is retracted to the top stand-by position. Open truck loading telescopic chutes, ship loading telescopic chutes and stockpile loading telescopic chutes have an extensive range of models and configurations depending on bulk material type, loading capacity and application requirements.

Closed Loading

Telescopic closed loading chutes are used to fill tanker trucks, barges and ships with closed containers. At the beginning of loading, the telescopic chute is lowered and stopped when it reaches to the tanker inlet. After that, product flow starts. Material falls freely through the inner side of the chute. Tanker is filled with the product. Air content of the tanker is transferred back through the chute and then discharged through the air vent. Level sensor located at the discharge point of the telescopic chute monitors the product level in the tanker and stops the operation when the tank is full. After loading is completed, the telescopic chute is retracted to the top stand-by position.

Advantages of Telescopic Chutes

- Dust-free loading.

- A working environment that is free of dust, prevention of dust pollution, and protection of the plant and the environment.

- Adaptable to a variety of systems used for the storage and conveyance of bulk materials.

- It is possible to load from various pieces of equipment, such as silos, hoppers, screw feeders, conveyors, etc.

- An extensive selection of models is offered to accommodate a broad spectrum of requirements.

- Auto raising functionality. When the loading process is complete, the chute will automatically retract, saving considerable operator time.

- There was no product waste, and there was no spillage.

- Loading materials with temperatures as high as 300 degrees Celsius is possible.

- Uncomplicated operation. – Low burden of maintenance.